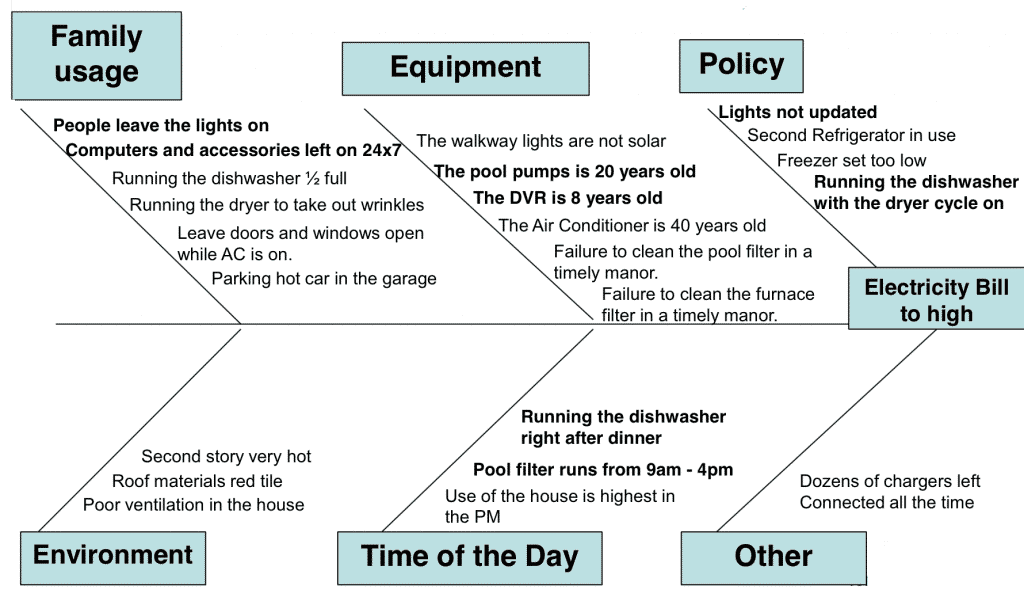

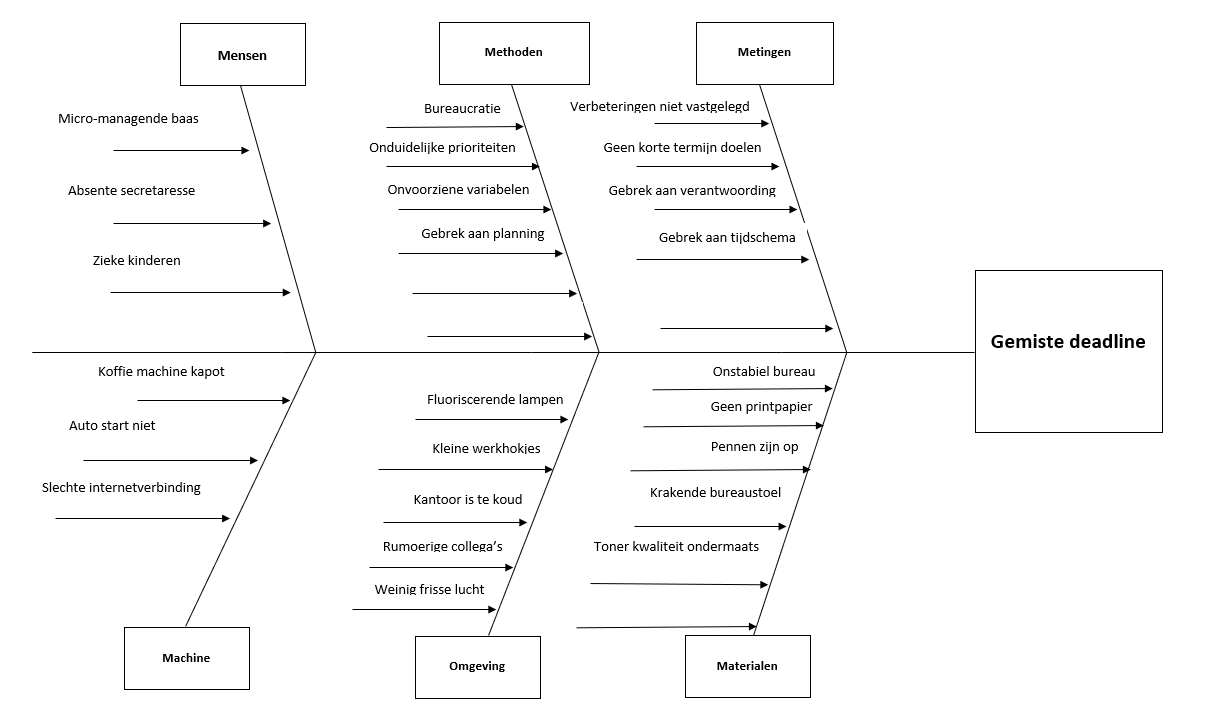

The name comes from the diagram's design, which looks much like a skeleton of a fish. After the group has brainstormed all the possible causes for a problem, the facilitator helps the group to rate the potential causes according to their level of importance and diagram a hierarchy. It should be efficient as a test case technique to determine cause and effect.Ī fishbone diagram is useful in product development and troubleshooting processes, typically used to focus a conversation around a problem. Typically used for root cause analysis, a fishbone diagram combines the practice of brainstorming with a type of mind map template. This tool is used in order to identify a problem’s root causes. CoursesĮxcerpted from The Quality Toolbox, Second Edition, ASQ Quality Press.A fishbone diagram is a visualization tool for categorizing the potential causes of a problem.

The authors explore how digitizing one of the seven basic quality tools-the fishbone diagram-using mind mapping can significantly improve the tool. Make one with the Six Sigma package in R.įish(bone) Stories ( Quality Progress) The method behind the fishbone diagram is older than many of its users.

Ishikawa diagram in six sigma software#

Quality Nugget: Creating Ishikawa (Fishbone) Diagrams With R ( Software Quality Professional) A fishbone diagram connects causal links in major categories with an outcome, or effect. The Quality Toolbox, Second Edition Articles Booksīusiness Process Improvement Toolbox, Second Edition You can also search articles, case studies, and publications for fishbone diagram resources. The resulting diagram illustrates the main causes and subcauses leading to an effect (symptom). Start using the fishbone diagram template and analyze process dispersion with this simple, visual tool. "Iron tools" can be considered a "Methods" problem when taking samples or a "Manpower" problem with maintenance personnel. "Calibration" shows up under "Methods" as a factor in the analytical procedure, and also under "Measurement" as a cause of lab error. Note that some ideas appear in two different places. Layers of branches show thorough thinking about the causes of the problem.įor example, under the heading "Machines," the idea "materials of construction" shows four kinds of equipment and then several specific machine numbers. The team used the six generic headings to prompt ideas.

This fishbone diagram was drawn by a manufacturing team to try to understand the source of periodic iron contamination. When the group runs out of ideas, focus attention to places on the chart where ideas are few.Layers of branches indicate causal relationships. Continue to ask "Why?" and generate deeper levels of causes. Write sub-causes branching off the causes. Again ask "Why does this happen?" about each cause.

Causes can be written in several places if they relate to several categories. Ask "Why does this happen?" As each idea is given, the facilitator writes it as a branch from the appropriate category.

0 kommentar(er)

0 kommentar(er)